Objectives

NEXTAIR brings together 16 partners from 6 countries, including 4 leading aeronautical industries, 3 innovative SMEs and 9 renowned research organisations. Together, they will develop and demonstrate innovative multi-disciplinary design methodologies, data-fusion techniques, and smart health-assessment tools enabling the digital transformation in aircraft design, manufacturing, and maintenance towards the next climate-neutral aircraft configurations. More specifically, NEXTAIR will develop Digital Enablers covering the whole aircraft life cycle (from the first design phases, including manufacturing aspects, up to operability) devoted to ease:

- breakthrough technology maturation by improving and advancing digital design models;

- flawless entry-into-service by efficiently accounting for all relevant sources of uncertainty;

- smart health-assessment by developing dedicated digital twinning methodologies.

Activities

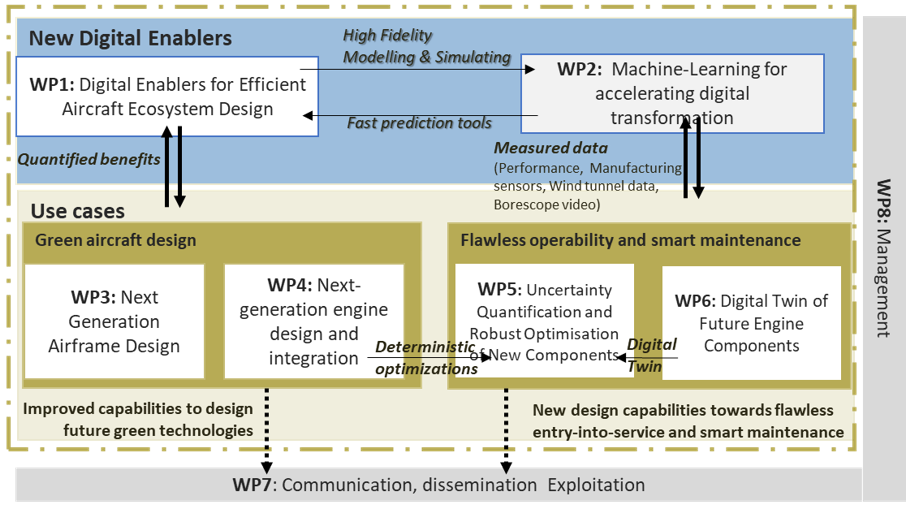

The project activities are implemented through 8 Work Packages (WP) with specific objectives:

WP 1 - Digital Enablers for Efficient Aircraft Ecosystem Design

- Deliver new digital models, as part of DENs, or model-based validation and certification for commercial aviation,

to be demonstrated and evaluated in application-centric WPs 3-6. - Ensure that the developed methods, workflows and codes, when used in WPs 3-6, will yield designs that can run

in realistic time scales faster than with the state-of-the-art tools.

WP2 - Machine learning for accelerating digital transformation

- Ensure that ML instruments are used in a principled way, by fully understanding the governing methodologies,

limitations, and inherent biases. - Guarantee that the methods, workflows, and codes passed to WPs 3-6 can yield end-to-end design, manufacturing and maintenance driven workflows that can run on realistic industry-deployable time scales and are a significant stepup from existing practices.

WP3 - Next Generation Airframe Design

- Enable the design of future climate-neutral aircraft configurations featuring strong disciplinary couplings at realistic timescales by applying and maturing smart and Hi-Fi multidisciplinary digital design tools.

- Investigate the design of two next-generation aircraft configurations using multidisciplinary Hi-Fi methods; for

small-medium range transport aircraft and laminar business jet and quantify the benefits of the newly developed capabilities in the context of the climate-neutral targets. - Bring Hi-Fi MDO closer to the decision-making circles in the aircraft industry by efficiently generating Pareto fronts for computationally intensive and industry-relevant green configurations.

WP4 - Next-generation engine design and integration

- Define a rational driving towards an extended design framework for overall aircraft-emission and noise reduction

while preserving the aero-propulsive gains envisaged by disruptive engine technologies. - Increase the knowledge regarding the most critical interaction effects between the engine and wing to be taken into account from the preliminary design stage with efficient yet accurate strategies.

- Implement modular workflows enabling the flexible integration of multiple disciplines and levels of fidelity to

tackle complex optimisation problems in engine design efficiently. - Demonstrate improved design capabilities for next-generation engine concepts and their airframe integration with respect to the state-of-the-art at the beginning of the project.

WP5 - UQ and Robust Optimisation for Flawless Entry into Service and Operability of New Components

- Ensure that the main sources of uncertainties are identified and considered when designing a new component.

- Apply more accurate and efficient UQ and RO techniques in the design of complex systems enabling the

acceleration of aircraft design process and supporting its flawless entry into service. - Extend the use of UQ and RO techniques from single disciplinary to MDO methods.

- Enhance the confidence in simulation-based data to accelerate and support the certification process.

WP6 - Digital Twin of Future Engine Components

- Implement a Digital Twin from measurements (scanned parts, boroscope images).

- Ensure that the Digital Twin performance can be estimated using appropriate simulations.

- Implement a fast prediction of residual performance and life using AI tools from WP2.

- Implement an approach to optimise maintenance/replacement of components & their schedule.

WP7 - Dissemination, Exploitation & Communication

- Establish and implement effective dissemination, communication, and exploitation strategy to ensure wide-scale

uptake of project results. - Monitor the management of the knowledge created and ensure open access to the results of NEXTAIR.

- Contribute, upon invitation by the CINEA, to common information and dissemination activities to increase the

visibility and synergies between HE/H2020 supported actions.

WP8 - Management

- Ensure efficient coordination and communication of the consortium with the EC and relevant stakeholders.

- Ensure an efficient technical, administrative and financial management of the project.

- Foresee any risks of delay and set up mitigation plans and corrective actions.

Work Plan

Test cases

Four relevant Technological Streams are identified in NEXTAIR based on their potential to contribute to greener aviation and their industrial relevance. For each Technology Stream, 2 Test Cases have been selected and will be implemented by dedicated teams.

TC1: HARW small-medium range aircraft

HARW technology poses major challenges for aero-structure design (flutter, handling qualities, and controllability,…). The main focus will be on using Hi-Fi MDO tools with new capabilities to account for dynamic constraints. In addition, robust design approaches to uncertainties on shape and structural parameters will be demonstrated.

Partners responsible: AIRBUS, ONERA, DLR, IRT, NTUA, FOSS, INRIA

TC2: Laminar HARW business jet configuration

NLF technology poses major challenges on transition modelling and robustness to shape deviations and manufacturing tolerance. The main focus will be on the Differential RSM enhancement via data-fusion, efficient MOO and robust NLF design to shape variations.

Partners responsible: DAV, NTUA, DLR, INRIA, FOSS

TC3: Ultra High Bypass Ratio Fan

Major design challenges are associated to performance degradation in off-design conditions (e.g. stall range, flutter, surge margin,…). and due to damage. The focus will be on multi-fidelity approaches to embed HiFi simulation data in MDO as well as on ML techniques for robust design (e.g. blade manufacturing envelope) and digital twinning of existing components.

Partners responsible: RR, UNICA, ICL, USFD, IRT

TC4: Unducted Single Fan

Open rotor technology leads to complex aerodynamic interactions between the fan and the outlet guide vanes becoming source of noise. The focus will be on more efficient algorithms to reduce the cost of aero-acoustic prediction, explore larger dimensional design spaces and master uncertainties via robust design.

Partners responsible: SAFRAN, ONERA, NTUA, IRT, INRIA

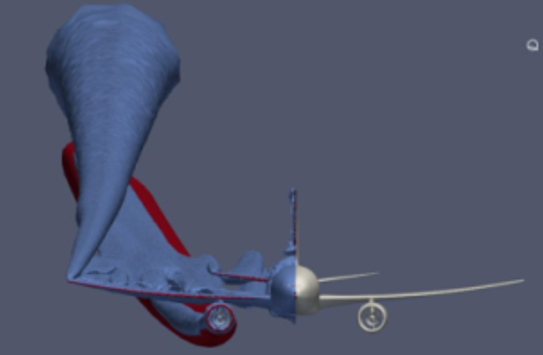

TC5: Wing-USF engine aero-propulsive interactions

Taking into account the aerodynamic field of the aircraft on the engine is mandatory and conversely. The focus will be on robust co-design exploiting the UQ framework as well as the adjoint body-force method for fully coupled aero-propulsive optimisations.

Partners responsible: ONERA, SAFRAN, IRT, INRIA

TC6: Wing-engine-exhaust interactions

Contrails introduce a major challenge to reduce climate aviation’s impact due to their higher radiative forcing effect. The focus will be on wing-engine design modifications to affect particle dispersion and dedicated MDO approaches for aerodynamic, acoustic performance and contrail generation trade-offs.

Partners responsible: RR, USFD

TC7: High-pressure turbine blades

Major design challenges are associated to multiple conflicting objectives (aerodynamics, thermal, structural and lifting), in the presence of significant uncertainties (BCs, manufacturing, deteriorations). The focus will on MOO with fast design space exploration enabled by multi-fidelity and ML-driven instant CFD as well as on robust MDO.

Partners responsible: RR, UNICA, ICL

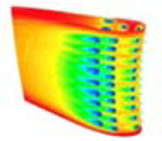

TC8: Heat exchanger for hybrid electric engines

HE represent a key component for future electric and hybrid engines. The main challenge is maximising the efficiency and compactness. The focus will be on removing conventional constraints on design space as enabled by topology optimisation and addictive manufacturing supported and improved by a digital twinning process.

Partners responsible: RR, IRT, OPT, VICOM

NEXTAIR's long-term impacts

Impact on industry

The aim is to deliver transformative digital and eco-efficient manufacturing technologies, advance further composite manufacturing, Maintenance-Repair-Overhaul and health assessment processes and procedures that will allow flawless entry into service and continuous airworthiness of European aircrafts of all platforms. In that regard, it will open the way to increased synergies and feedback among design, manufacturing, and MRO phases in the aircraft life cycle.

Impact on

society

The aim is to increase green technologies in aviation, consequently reducing aviation sector impact on the environment (CO2, non-CO2, noise…). In other words, such project will allow to reduce fuel burn and CO2 between the existing in-service aircraft and the next generation.

Impact on science

The project will generate a new breakthrough on enablers for the digital transformation of European industry.

Impact on economy

Digital transformation in the aviation industry substantially impacts all areas of the industry's supply chain, such as air traffic management, aircraft operations, aircraft, and component manufacturing. NEXTAIR will help EU players to have a leadership position in the growing aviation digital transformation market (for example, MRO market is projected to grow from €520 million in 2020 to €1,500 million by 2030).

Aircraft design procedures will routinely benefit from smart ingestion of increasing available real data. The smart pairing will continuously improve the operability of manufactured and in service components with more accurate and faster virtual predictions.

NEXTAIR tools will also support the development of any new aircraft configurations, following the evolution of the aviation sector. NEXTAIR will offer key enablers to the European aviation industry to adapt to new market organization and needs, or new forms of mobility, therefore contributing to its competitiveness. In a nutshell, it is expected to increase efficiency of the design process (reduction of cost and time needed).

Funded by the European Union under the GA number: 101056732. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union. Neither the European Union nor the granting authority can be held responsible for them.

Copyright ©. Tous droits réservés.

Nous avons besoin de votre consentement pour charger les traductions

Nous utilisons un service tiers pour traduire le contenu du site web qui peut collecter des données sur votre activité. Veuillez consulter les détails dans la politique de confidentialité et accepter le service pour voir les traductions.